High rigidity die locking system contents with high speed machine.It is impact- resistant and has long service life.

High quality and wear resistance casting platen adopts finite element analysis design that brings even stress distribution to increase die locking precision

Adopts automatic concentrated lubrication system to improve machine service life and decreases repair times.

Hydraulic drive gear type mould height adjustment with convenient operation and accurate adjustment.

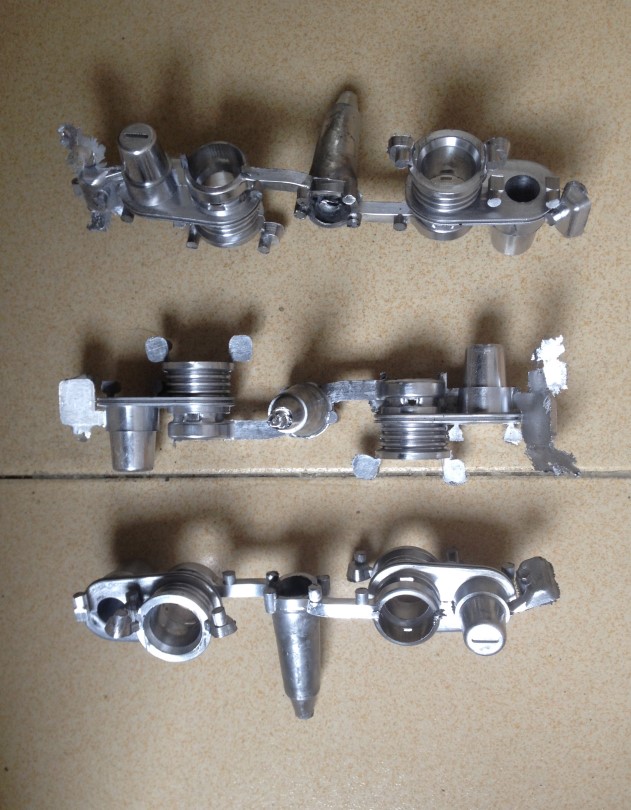

Imported hydraulic valves ensure hydraulic system working stability and excellent performance

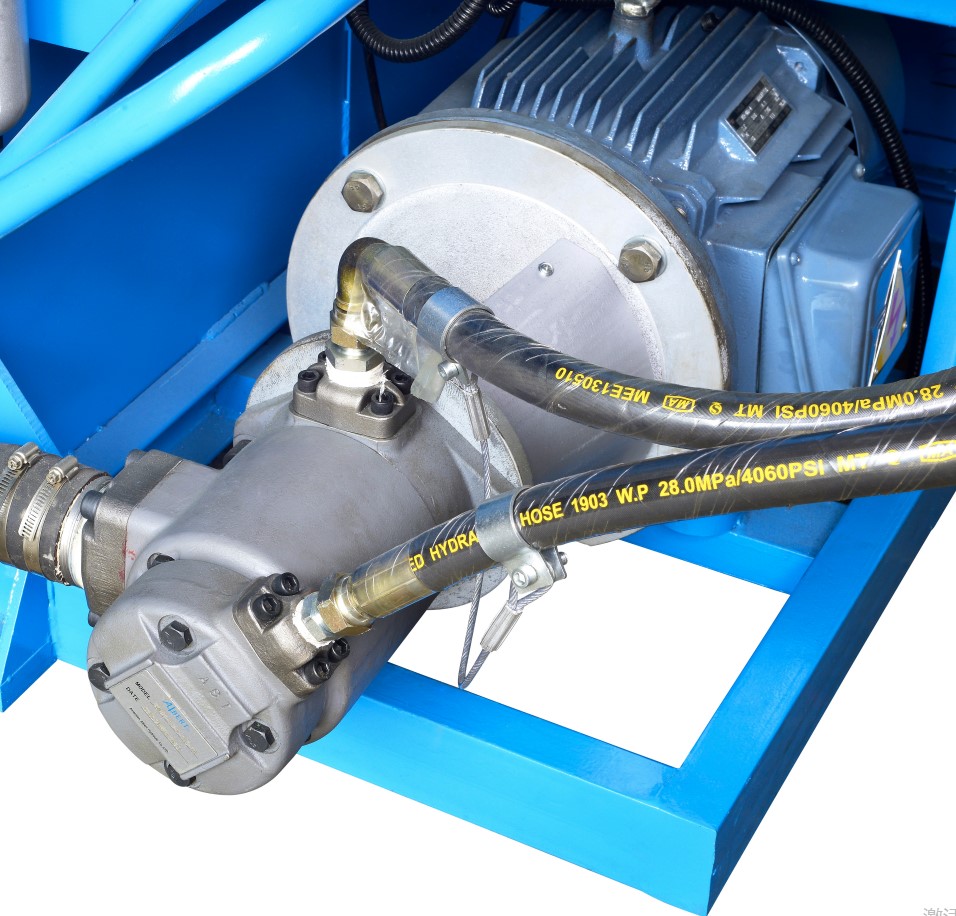

Good quality hydraulic pump with high performace and low noise

Adopts Siemens/Delta/Omron PLC control system,can control and supervise the date and states of every movement,which is convenient for operation and maintenance.

The system is equipped with self diagnosing and failure alarm function for convenient removal failures

The screen LCD monitor can realize conversion between chinese, english and other language

DC50T Hot Chamber Die Casting Machine Technological Date

|

ITEM |

Unit |

DC50T |

|

Clamping Force |

KN |

500 |

|

Clamping Stroke |

mm |

200 |

|

Ejection Force |

KN |

50 |

|

Ejection Stroke |

mm |

60 |

|

Die Thickness (Min-Max) |

mm |

120-330 |

|

Platen Size(HxV) |

mm |

500-480 |

|

Space Between Tie Bars(W×H) |

mm |

335X285 |

|

Tie Bar Diameter |

mm |

55 |

|

Injection Position |

mm |

0 |

|

Injection Stroke |

KN |

105 |

|

Traverse Stroke |

mm |

190 |

|

Injection Force |

mm |

65 |

|

Diameter Of Plunger |

mm |

40/45/50 |

|

Max Casting Force |

Bar |

517/409/331 |

|

Shot Weight |

Dm³ (kg/zn) |

0.85/1/1.3 |

|

Max Projecting Area |

cm² |

73/93/115 |

|

System Pressure |

Mpa |

10 |

|

Motor Power |

KW |

7.5 |

|

Crucible Capacity |

Kg |

325 |

|

Oil Consumption |

Kg/h |

3.8 |

|

Oil Tank Capacity |

L |

200 |

|

Weight Of Machine |

Kg |

3.3 |

|

Machine Size (L×W×H) |

mm |

3550X1450X2000 |

Product Catalog

Quick Navigation

We're Here to Help

![]() +8613794657349

+8613794657349![]() sukiyoung1220@gmail.com

sukiyoung1220@gmail.com![]() wjyz168@163.com

wjyz168@163.com![]() B5 District, Qujiang Economic Development Zone, Shaoguan City, Guangdong Province

B5 District, Qujiang Economic Development Zone, Shaoguan City, Guangdong Province