Magnesium Alloy Dosing And Holding Furnace

*Low energy consumption,high melting rate;

*Perfect gas-mixing station promises thoroughly mixing of gas,smooth flow

*The crucible made of imported dual metal steel plate is characterized by longer service life and contamination free;

*Temperature in the hearth and chamber are controlled by separative thermocouples;

*Automatic alarm devices for overtemperature,leakage,lack of gas etc.

*Dosing pump precisely control the casting time and speed,high repeatability and dosing,high-temperature and corrosion resistance,non derforming,work stably in melted magnesium,extraction pipe,easy to clean,servo motor drive,and resistance-controlled.

*Transfer tube is made of special steel and characterized by high temperature and corrosion resistance,non deforming,anti oxidation,long service life and ensure the purity of molten metal as well as the precise dosing and safely.

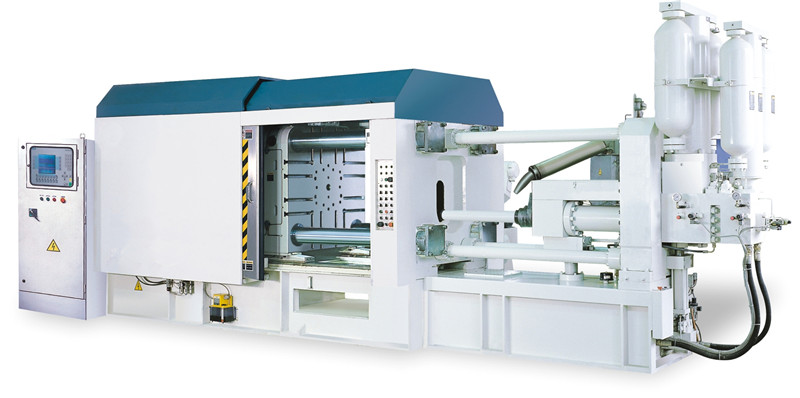

DC630T Cold Chamber Magnesium Die Casting Machine Technological Date

|

ITEM |

Unit |

DC630T |

|

Clamping Force |

KN |

6300 |

|

Clamping Stroke |

mm |

650 |

|

Die Thickness (Min-Max) |

mm |

350-900 |

|

Platen Size(HxV) |

mm |

1225X1310 |

|

Space Between Tie Bars(W×H) |

mm |

750X750 |

|

Tie Bar Diameter |

mm |

160 |

|

Injection Force |

KN |

590 |

|

Injection Stroke |

mm |

600 |

|

Diameter Of Plunger |

mm |

70/80/90 |

|

Shot Weight (Al) |

Kg |

4.3/5.7/7.2 |

|

Casting Pressure (Intensification) |

Mpa |

153/118/92 |

|

Max Casting Area (40Mpa) |

cm² |

1575 |

|

Injection position |

mm |

0, -250 |

|

Plunger Penetration |

mm |

250 |

|

Casting Flange Diameter |

mm |

165 |

|

Casting Flange Protrusion |

mm |

15 |

|

Ejection Force |

KN |

315 |

|

Ejection Stroke |

mm |

150 |

|

System Working Pressure |

Mpa |

16 |

|

Motor Power |

Kw |

37 |

|

Oil Tank Capacity |

L |

1100 |

|

Machine Weight |

Ton |

27.6 |

|

Machine Dimension |

mm |

7500x2000x2900 |

Product Catalog

Quick Navigation

We're Here to Help

![]() +8613794657349

+8613794657349![]() sukiyoung1220@gmail.com

sukiyoung1220@gmail.com![]() wjyz168@163.com

wjyz168@163.com![]() B5 District, Qujiang Economic Development Zone, Shaoguan City, Guangdong Province

B5 District, Qujiang Economic Development Zone, Shaoguan City, Guangdong Province